Vertiv™ CoolChip CDU

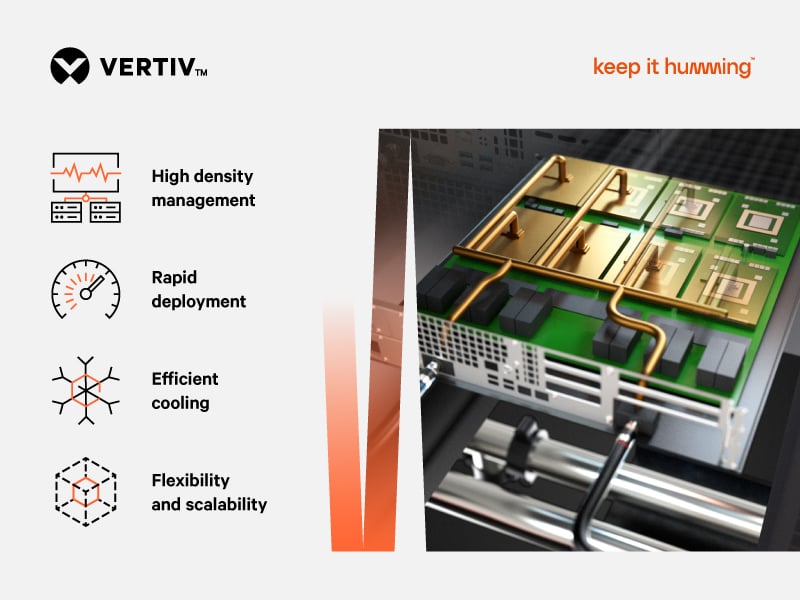

Designed to support liquid cooling within high density environments, the Vertiv CoolChip CDU is the next generation of coolant distribution units. They are suitable for direct-to-chip and rear door cooling applications that offer easy, cost-effective deployment in any data center. The CoolChip CDU family offers multiple system designs that operate with and without access to facility water, allowing you to tap into the benefits of liquid-cooled servers to more efficiently support higher rack densities. Select between in-rack, in-row, or perimeter-based designs as well as liquid-to-liquid or liquid-to-air heat exchangers.

Se ha guardado este producto en su panel

Acaba de guardar este producto en su panel para verlo más tarde. Cuando ya no necesite tener el contenido guardado, puede eliminarlo fácilmente de su panel.

Inicie sesión o cree una cuenta para guardar esto más tarde

- Data Center/Colocation/Hosting

- Education

- Government

- Healthcare

- Retail and Wholesale

Vertiv™ CoolChip CDU

Designed to support liquid cooling within high density environments, the Vertiv CoolChip CDU is the next generation of coolant distribution units. They are suitable for direct-to-chip and rear door cooling applications that offer easy, cost-effective deployment in any data center. The CoolChip CDU family offers multiple system designs that operate with and without access to facility water, allowing you to tap into the benefits of liquid-cooled servers to more efficiently support higher rack densities. Select between in-rack, in-row, or perimeter-based designs as well as liquid-to-liquid or liquid-to-air heat exchangers.

- Data Center/Colocation/Hosting

- Education

- Government

- Healthcare

- Retail and Wholesale

Especificaciones

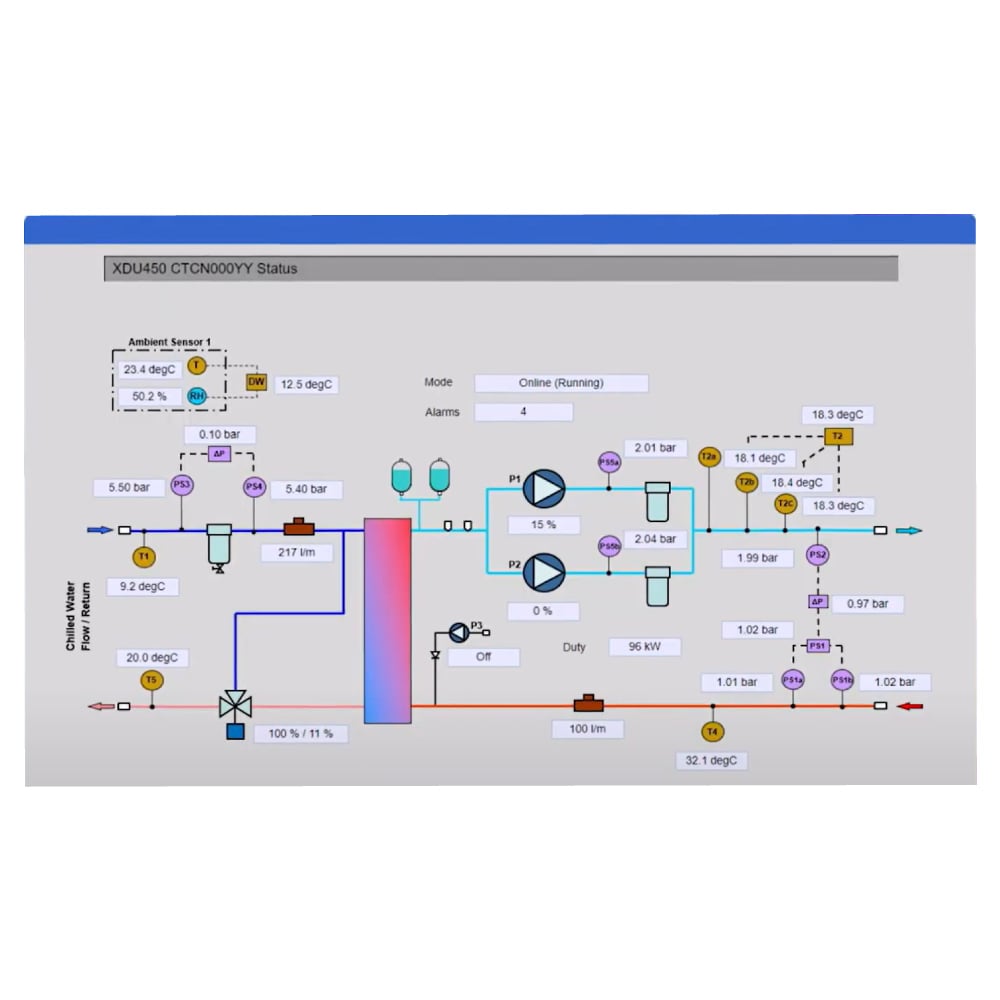

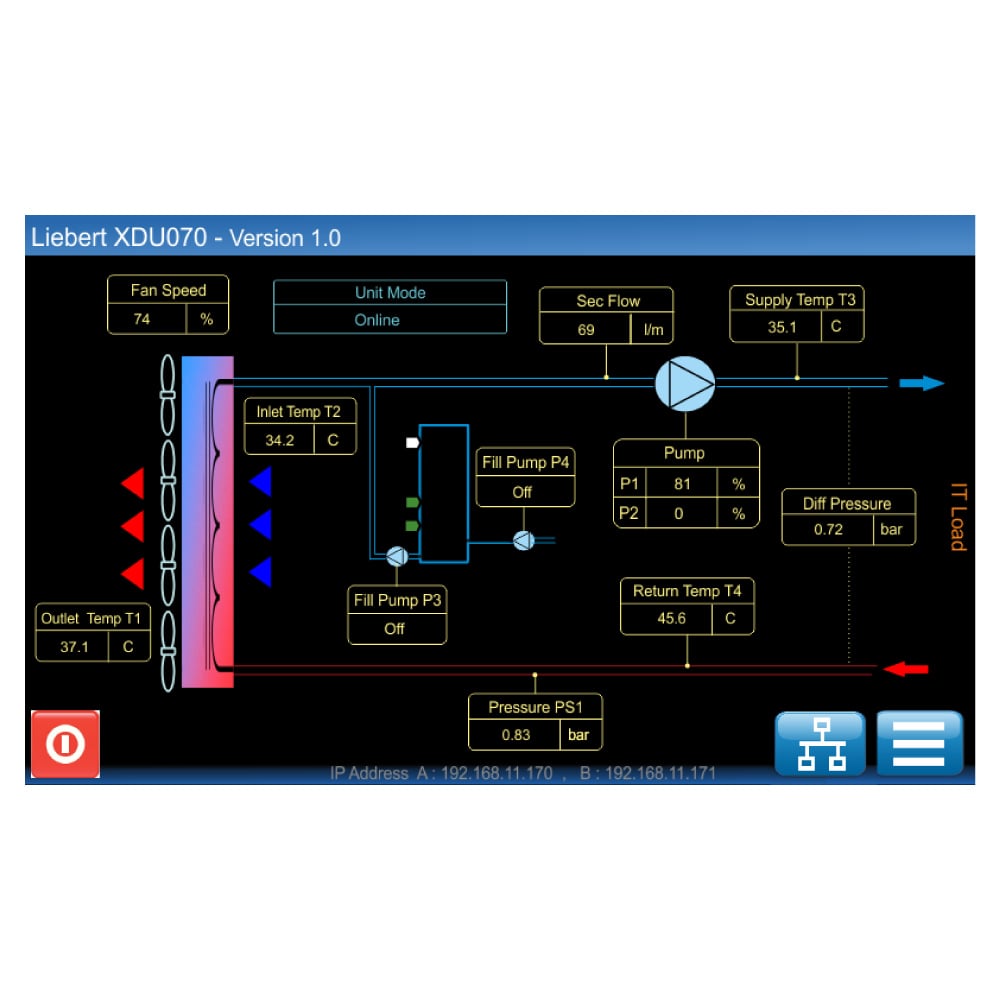

As data centers adopt liquid cooling, fitting in new coolant distribution infrastructure can be a real challenge. From hyperscale and colocation environments to edge applications, the Vertiv™ CoolChip CDU (the next generation of the Liebert® XDU family) simplifies your work with the flexibility to support rear door heat exchangers or direct to chip liquid cooling. The Vertiv CoolChip CDU’s compact footprint allows for in-rack, end of row, or perimeter placement options. However, and wherever you incorporate the Vertiv CoolChip CDU, you can easily distribute coolant to efficiently manage power-dense hot spots with liquid-to-liquid heat exchange up to 100 kw, 450 kW, 600 kW, or 1,350 KW, and liquid-to-air heat exchange up to 70kW. The Vertiv CoolChip CDU provides a compact footprint for deployment flexibility, efficient coolant distribution to manage power dense hot-spots, precise temperature control to eliminate thermal shock, redundant pumps and dual power feeds for reliable operation, and remote monitoring and communications for added peace of mind.

|

Liebert® XDU1350 Coolant Distribution Unit

|

|||||

|---|---|---|---|---|---|

| 1368 kW at 7.2°F (4°C) | N/A | 684 in | 35.4 in | 48.9 in | 1431 lbs |

| Ver más información del producto | |||||

|

Liebert® XDU450 Coolant Distribution Unit

|

|||||

| 453 kW at 7.2 °F (4.0 °C) | N/A | 74.8 in | 23.6 in | 41 in | 848 lbs |

| Ver más información del producto | |||||

|

Vertiv™ CoolChip 070 CDU

|

|||||

| 70.0 kW at 11C approach temperature difference | 10,100 m3/h (5,945 CFM) | 91 in | 24 in | 48 in | 899 lbs |

| Ver más información del producto | |||||

|

Vertiv™ CoolChip CDU, 100

|

|||||

| N/A | 6.8 in; 4RU | 17.5 in | 34.2 in | 130 lbs | |

| Ver más información del producto | |||||

|

Vertiv™ CoolChip CDU, 600

|

|||||

| 600kW at 7.2 F (4.0 C) approach temperature difference | N/A | 78.7 in | 23.6 in | 47.2 in | 1058 lbs |

| Ver más información del producto |

Beneficios

Características

- Liebert® XDU1350 Coolant Distribution Unit Operation and Maintenance Manual (SL-70619)

- Vertiv™ CoolChip CDU 600 Installation and Commissioning Guide

- Vertiv™ CoolChip CDU100 Installation and Commissioning Guide SL-71337

- Vertiv™ CoolChip CDU100 Operation and Maintenance Manual SL-71338

- Liebert® XDU450 Coolant Distribution Unit Application and Planning Guide (SL-70616)

- Liebert® XDU070 Operating and Maintenance Guide

- Liebert® XDU1350 Coolant Distribution Unit Installation and Commissioning Guide (SL-70625)

- Vertiv™ Liebert® XDU1350 Coolant Distribution Unit Operation and Maintenance Manual XDU1350B SL-71310.pdf

- Vertiv™ CoolChip CDU 600 Operation and Maintenance Guide SL-07626.pdf

- Vertiv™ CoolChip CDU 600 Application Guide SL-07624

- Vertiv™ Liebert® XDU1350 Coolant Distribution Unit Application and Planning Guide XDU1350B SL-71309

- Vertiv™ Liebert® XDU070 Coolant Distribution Unit (Liquid to Air) Application and Planning Guide SL-71111.pdf

- Liebert® XDU450 Coolant Distribution Unit Operation and Maintenance Manual (SL-70617)

- Liebert® XDU070 Coolant Distribution Unit Installation and Commissioning Guide (SL-71110)

- Guidelines for Deployment of Single Phase Technology Cooling System SL-80056.pdf

- Liebert® XDU450 Coolant Distribution Unit Data Sheet (SL-07622)

- Vertiv™ CoolChip CDU 600 Data Sheet SL-80061

- Liebert® XDU1350 Coolant Distribution Unit Data Sheet (SL-70799)

- Vertiv™ CoolChip CDU 100 Data Sheet

- Vertiv™ Liebert® XDU070 Data Sheet (SL-71252)

- Vertiv CoolChip CDU 350kW Data Sheet SL-71957

- Vertiv™ Liquid Cooling Services SL-71351

*Para ver las descargas específicas del modelo, necesita ir a la página de producto seleccionando el nombre del producto en el gráfico de especificaciones que aparece más arriba.