Proactive UPS Battery Replacement Is Critical to Power Protection

UPS batteries are an important and integral part of your critical power protection system. Indeed, the uninterruptable power supply (UPS) that protects and supports your critical loads is only as reliable as the vented lead-acid (VLA or “flooded”) or valve-regulated lead-acid (VRLA) batteries that back it up.

Vertiv™ VRLA battery

In the event of a power outage or other power anomalies outside of normal operation, strings of batteries provide power to the UPS, providing several minutes of ride-through time, during which the critical load switches over to an auxiliary power source, a device such as a second utility feed or generator. When adequate power is restored to the UPS, the battery will automatically be recharged in preparation for the next outage.

However, if any individual battery in a string fails, then so can the UPS. According to the Uptime Institute, power-related outages account for 43% of outages that are classified as significant. The single biggest cause of power incidents is uninterruptible power supply (UPS) failures, making UPS batteries the weakest link in a power protection strategy, with each battery representing a potential point of failure.

Uninterruptible Power Supply Battery Service Life

The service life of most UPS systems is around seven to 10 years. A traditional VRLA battery typically lasts three to five years. So, a replacement battery will be needed at least once or twice during the lifetime of your UPS. Knowing when and how to replace UPS batteries is critical to ensuring the availability of your UPS when you need it most.

UPS batteries are built to provide several years of service, operating reliably even through repeated charging and occasional use while supporting critical loads. But like any battery, Lead-acid batteries have a defined lifecycle. A UPS battery can only handle a finite number of discharge and recharge cycles—generally up to 300 full discharges—before it fails and must be replaced.

Many factors can shorten that lifecycle, including high operating temperatures, corrosion, undercharging and overcharging, shorted or open cells, dry out, and aging. Application, installation, real-world operating conditions, and maintenance practices impact battery service life. It’s essential to remember that with lead acid batteries, a controlled room temperature of 77 ̊F (25 ̊C) is necessary to ensure a three-to-five-year lifespan. With every 15 ̊C increase in room temperature, the useful life of a typical VRLA battery is cut in half.

The key is to know when your UPS batteries are nearing the end of their life expectancy so that they can be replaced before they get to the point where they fail to protect your load in a critical situation, such as a complete power outage.

UPS Battery Capacity and End of Life (EOL)

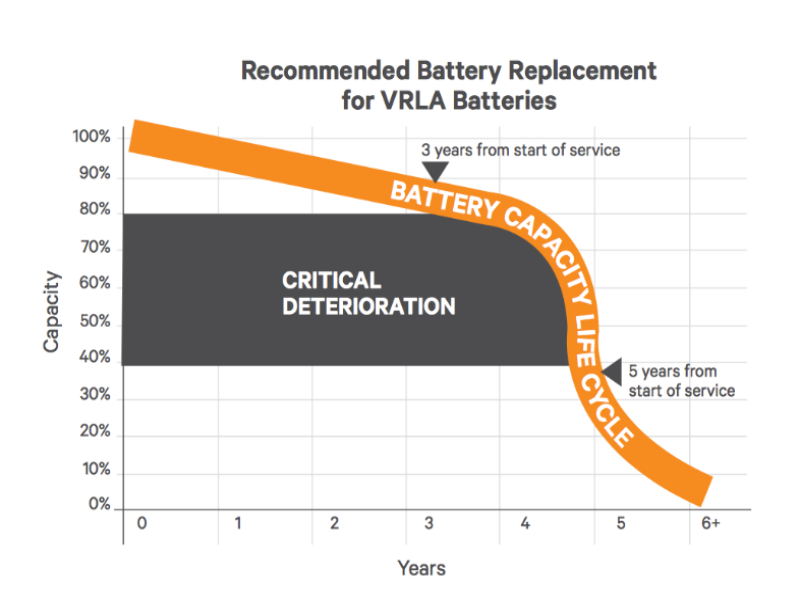

UPS battery capacity depletes over time. The typical VRLA battery's capacity begins to drop off after three years of use, and the drop becomes even steeper after five years. Between years three and five, the battery is considered to be in a phase of critical deterioration.

Life span of a VRLA battery

When a Lead-acid battery reaches 80% capacity, it is considered at the end of life (EOL). Institute of Electrical and Electronics Engineers (IEEE) standards recommend replacing a battery when its capacity is below 80%. Performance degradation of old batteries typically accelerates at this point, and the battery loses its ability to provide sufficient voltage. In addition, older Lead-acid batteries may be vulnerable to “sudden death syndrome,” unlike lithium batteries, in which a battery works fine one day but fails to provide sufficient power the next day, resulting in a UPS failure and data center downtime.

UPS Battery Maintenance and Testing

A great way to keep tabs on the health of batteries is through a battery preventive maintenance program. Some people overlook UPS battery maintenance because the batteries are marketed as maintenance-free options However, this only means that the batteries do not require electrolyte fluid replenishment. UPS batteries can greatly benefit from regular inspections and battery cleaning, ideally every three to six months.

Periodic testing and assessment of UPS batteries is also a great idea. This can include ohmic testing for battery aging status, load bank testing, and infrared inspection to detect possible battery overheating. The results of these tests and inspections can provide meaningful data for estimating battery EOL. Keeping an eye on UPS battery runtime can also help with these estimates. When runtime decreases in battery mode, it can signal battery depletion. Companies should consider performing battery runtime tests once or twice a year, especially as your batteries age.

Battery Testing and Maintenance

Some organizations also use battery monitors to track the status of UPS batteries continuously. The monitors check the state of health of each cell by performing a proactive resistance test, which is considered a reliable predictor of battery performance. The monitoring systems can provide alerts and early warnings if they detect potential battery problems.

Proactive Battery Replacement

Proactively replacing UPS batteries according to an adequate UPS battery replacement schedule will allow power back-up systems to run to specifications and ultimately maximize the uptime of business operations. UPS battery replacements can be completed through professional full-string replacement and installation of new cells. Some UPS models feature hot swappable, user-replaceable batteries that can be installed quickly using battery replacement kits.

Experience seamless UPS replacement and gain peace of mind with our expert Vertiv UPS technicians on-site, ensuring smooth operation and timely adjustments after battery replacement, keeping your critical systems protected at all times. In addition, you will need to recycle used batteries via certified contractors and in compliance with all local environmental requirements.

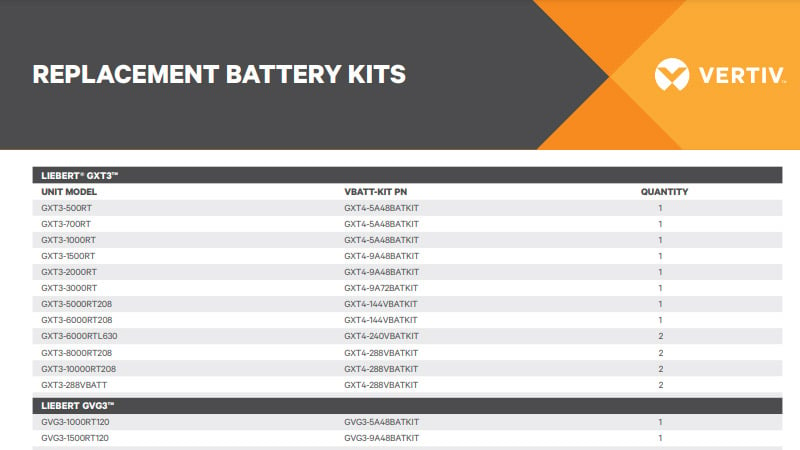

Replacement Batteries Services Available from Vertiv

Vertiv offers complete maintenance services for UPS battery systems designed to maximize battery performance and unit uptime. Services include inspections, testing, and battery cleaning and full-string UPS battery replacement, including expert installation of new cells and certified recycling of used UPS batteries. Vertiv also offers battery kits to streamline battery replacement for several single-phase UPS families, including Vertiv™ Liebert® GXT3, Vertiv™ Liebert® GXT4, Vertiv™ Liebert® GXT5, and Vertiv™ Edge Single Phase UPS. Battery kits are kept in stock locally, ensuring they are ready to ship to your sites whenever and wherever needed.

Visit the Vertiv™ UPS & Battery Services page to learn more about solutions for ensuring total power system availability.