The data center industry continues to develop larger and larger data centers to meet capacity demands, while at the same time is taking steps to significantly reduce the impact of data centers on the environment.

Companies like Vertiv design with sustainability in mind, developing data center solutions that help meet the needs of the present without compromising the ability of future generations to meet their own needs. Chilled water systems can play an important role in this evolution. They allow owners and operators to develop new data centers that efficiently address both direct and indirect emissions, which are factored into the total equivalent warming impact (TEWI) metric.

Understanding a Chilled Water System

In a chilled water system, the cooling units (Computer Room Air Handlers – or CRAHs) are connected to a chiller outside the data center that provides the chilled water used by the cooling units. Warm water from the cooling units is pumped back to the chiller where the heat is rejected from the water through a refrigeration system before returning cold water back to the air handlers.

1. Vertiv>™ Liebert® AFC - Large Capacity Up to 2.2 MW

2. Vertiv™ Liebert® AFC - Scroll Compressors

3. Vertiv™ Liebert® AFC- Screw & Inverter Screw with low-GWP Refrigerant

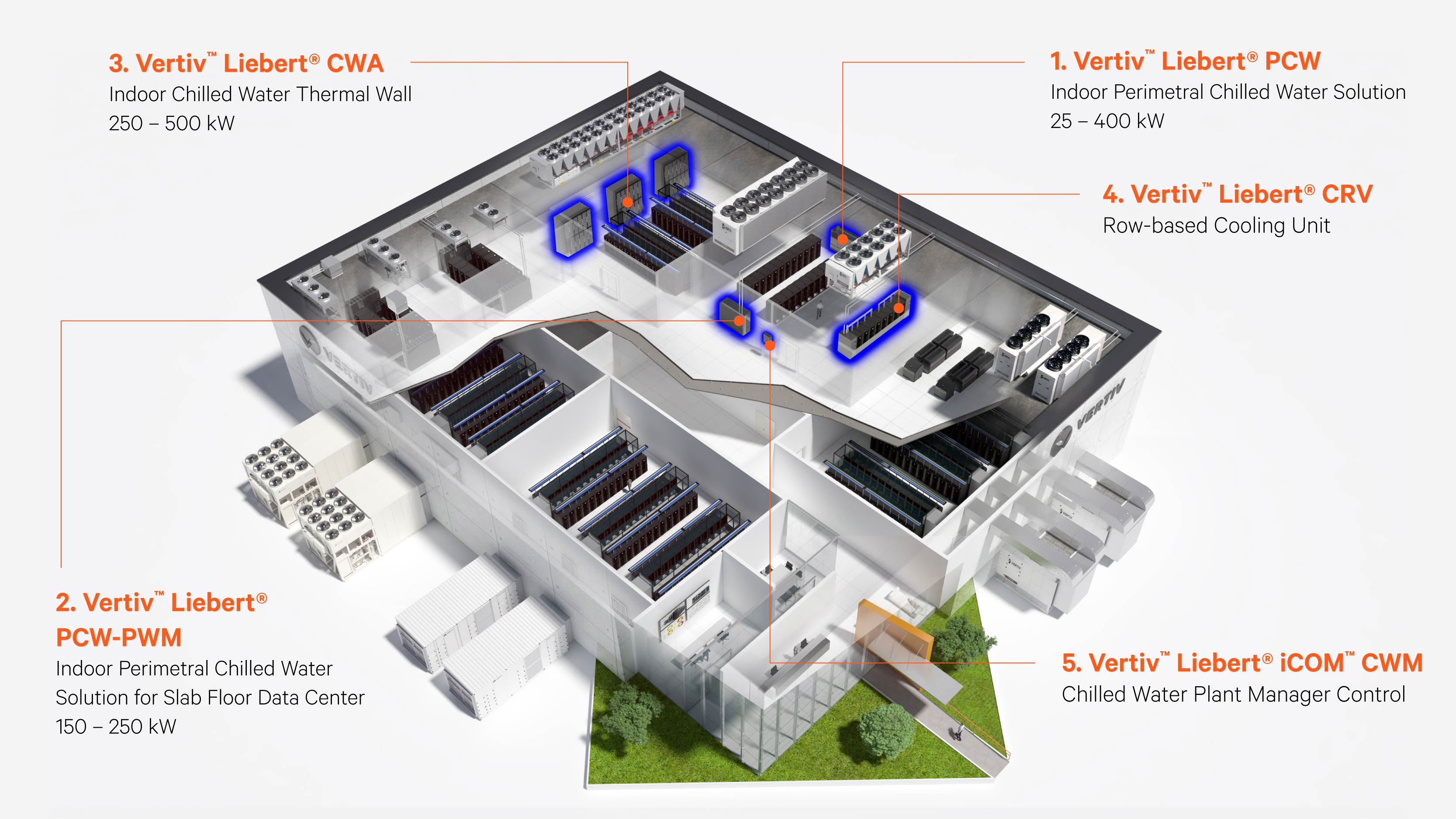

Vertiv has designed its indoor chilled water data center cooling systems to set new efficiency targets and to help cooling continuity for mission-critical workloads.

Perimeter cooling solutions also allow meeting the demands in case of non-raised floor applications addressing business and technical considerations such as reduced floor space, ensuring optional temperature and operations, improving protection, increasing efficiency, and simplifying deployment.

Moreover, chilled plant managers controls maximize chilled water system efficiency optimizing it as a whole by coordinating operation of the external units with the internal ones.

Rear-door heat exchangers are a mature technology that provide a viable solution for managing densities above 20 kW. These systems can form the foundation for a hybrid approach to data center cooling in which liquid and air-cooling systems work.

The next phase, in this evolution, is the move to direct liquid cooling that deliver high quality fluid to the racks, precisely controlling temperature, pressure, and flow rate to maximize efficiency and match the required cooling demand.

The two most common approaches to direct liquid cooling are direct-to-chip cold plates and immersion cooling.

With immersion cooling, servers and other components in the rack are submerged in a thermally conductive dielectric liquid or fluid. This approach maximizes the thermal transfer properties of liquid and is the most energy efficient form of liquid cooling.

3. Vertiv™ Liebert® VIC

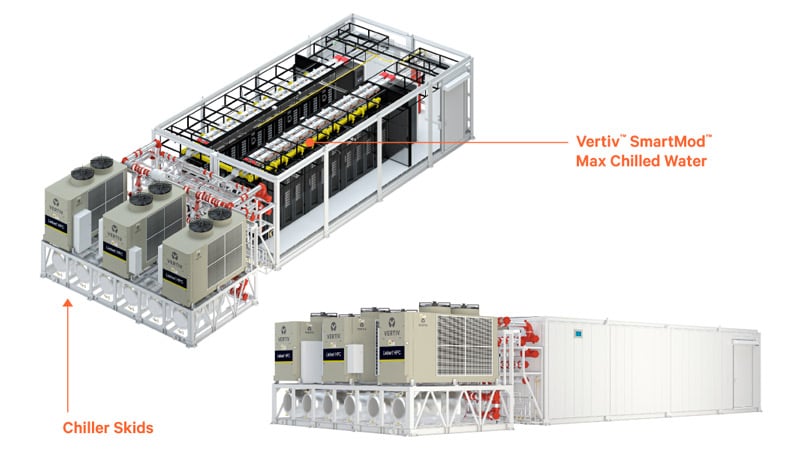

Modular data centers are pre-engineered, prefabricated, and standardized buildings, equipped with power and cooling, that house servers and network equipment. The types of modular data centers include container data centers, prefabricated data halls, and prefabricated power & cooling modules. Our SmartMod™ family consists of these modular data centers that can go from a single module solution - 100kW IT load or 14 IT racks - up to a dual module solution that can offer up to 210kW IT load, 26 IT racks with either direct expansion or chilled water thermal solution.

Vertiv™ SmartMod™ Max CW extends the capability of the already existing SmartMod™ platform to larger deployments. You can rapidly achieve your objectives, and you don’t have to overspend the budget or overbuild based on uncertain future needs. SmartMod™ Max CW is a two-module type of all-in-one data center that best suits IT deployments up to 210kW and up to 24 IT racks. Configured with two rows of racks, the system uses hot aisle containments to ensure optimal performance and Chilled Water as the thermal management system.

Analyzing the Environmental Impact of Chilled Water Systems

Sustainability has become one of the most important strategies for businesses and government organizations and will be a major force shaping the future. Chilled Water systems can play a major role in improving the carbon profile of data centers considering, in many facilities, approximately 25-35% of data center energy consumption can be attributed to air conditioning.

What are Direct Emissions

Direct emissions are related to a direct release into the atmosphere due, for example, to a leakage of a refrigerant fluid that can have a significant greenhouse effect, thus increasing the average global temperature.

Why chilled water systems are effective at reducing direct emissions?

-

Limited overall refrigerant charge per kilowatt (kW) of cooling. In some cases, the refrigerant may not even be required with data centers located in cold climates where heat is released through drycoolers or cooling towers.

-

The refrigerant is stored in the chiller units located outside the datacenter. The refrigerant circuit is also typically tested in the factory to exclude leakages, and further tested on-site after installation. This minimizes the potential risk of refrigerant losses.

-

Use of a range of refrigerants to limit the impact on the atmosphere, including hydrofluoro-olefin (HFO) and HFO-blended refrigerants that have a much lower GWP than traditional refrigerants.

What are Indirect Emissions

Indirect emissions take into account the production of electricity used by the system during its operation.

The more efficiently a unit operates, the less energy is required and the lower is its impact on indirect emissions.

Why chilled water systems are effective at reducing indirect emissions?

-

Inverter-driven compressors: to achieve higher efficiency levels, especially at partial loads cutting down electricity consumption.

-

Freecooling technology: it allows the cooling of the system without activation of the compressor.

-

Adiabatic technology: it additionally improves the efficiency as the ambient air is cooled down by passing through wet pads. It is then delivered at a lower temperature, achieving a higher freecooling capacity of the chiller and a more efficient operation of the compressor.

-

Onboard unit controller: it enables the use of water whenever strictly needed preventing water from being wasted.

-

Chilled plant manager control technology coordinates the operation of all the units and their main components allowing the integration and the coordination of the working mode between units and the main components.

Metrics: How to Calculate the Impact of Chilled Water Solutions

With effective use of low-GWP refrigerants, minimal risk of leaking, and a low pPUE and WUE, chilled water systems provide low impact thermal management both for raised floor and non-raised floor data centers.

The combination of low TEWI and low WUE makes chilled water systems one of the most sustainable choices for data center thermal management in terms of energy and water efficiency.

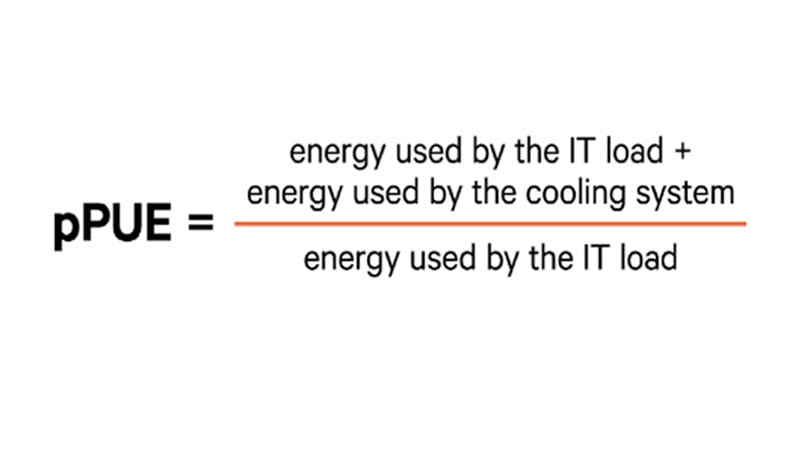

pPUE

pPUE - Partial Power Usage Effectiveness is ratio between the sum of energy used by the IT load and the cooling system divided by the energy used by the IT load. The lower the value, the more efficient the cooling system.

A pPUE of 1 would represent a data center in which every watt of energy is being used by IT equipment and the cooling system uses no energy.

Today’s Vertiv chilled water systems have the potential to support pPUE values lower than 1.1.

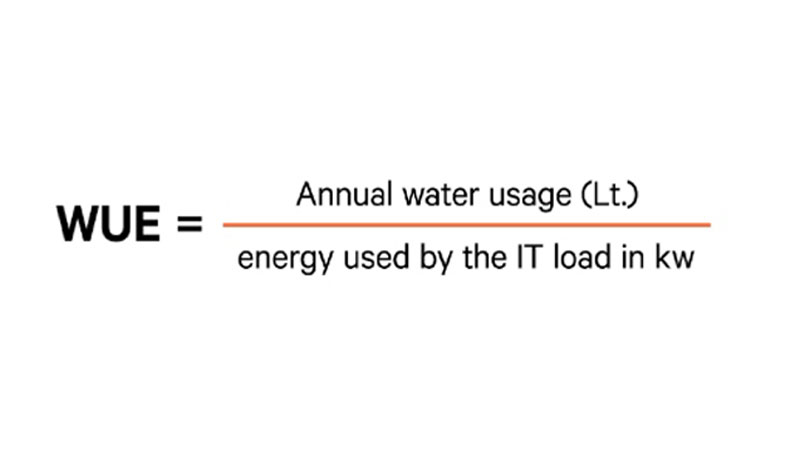

WUE

WUE – is the ratio between the annual site water usage in liters divided by the IT equipment energy usage in kilowatt-hours (kWh).

This metric is particularly valuable for those operating in a high stress water region.

Vertiv chilled water solutions use onboard controllers to enable the use of water strictly when needed based on redundancy, efficiency, or cooling demand. The controller’s primary job is to prevent water from being wasted, reducing the WUE of the data center.

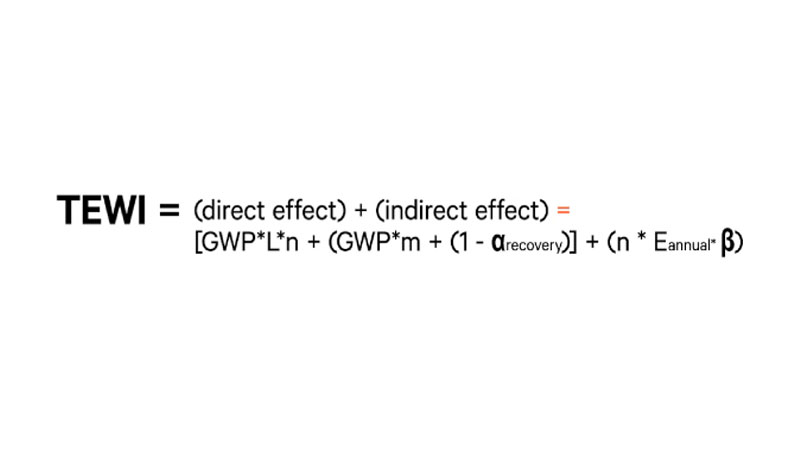

TEWI

TEWI is the algebraic sum defined under the Montreal Protocol, which represents the direct and indirect effects of the total carbon emissions of a cooling technology through its operating cycle.

It serves as a valuable metric in evaluating how well a particular cooling system can support the move to carbon neutrality because it encompasses both the role of refrigerants and the energy consumed by the system.

Legend:

GWP = Global warming potential (CO2 eq. kg)

L = Leakage rate per year (kg/year)

n = System operating time (years)

m = Refrigerant charge (kg)

αrecovery = Recycling factor

Eannual = Energy consumption per year (kWh)

β = CO2 emission per kWh

Optimizing Chilled Water Systems

Following are the optimization strategies that help chilled water systems to achieve excellent efficiency

![]()

Increasing Air and Water Temperatures

Move from chillers to more advanced freecooling chillers.

In just a few years, inlet air and water temperatures have risen significantly. This allows for an increased use of free-cooling technologies which can exploit cold external air temperatures as the main source of cooling, limiting the use of the compressor to cover the peaks occurring in the hottest periods of the year.

![]()

Optimizing the Chilled Water System Control as a whole

Use of Plant Manager Control such as the Vertiv™ Liebert® iCOM™ CWM.

To maximize chilled water system efficiency, it is important to consider the system as a whole by coordinating operation of the external units with the internal ones. The use of the chilled water plant managers control, such as the Vertiv™ Liebert® iCOM™ CWM, allows the coordination of the operation of all units:

- reducing the consumption of the pumps

- increasing the return temperatures of the fluid to the chillers

- optimizing the operating water temperature.

![]()

Improved Compressor Technology

Use of the inverter driven compressors.

In a data center located in a mild climate, a large part of the total energy absorption is due to the chiller compressor. The use of innovative and efficient inverter driven compressor technologies can therefore help achieve improved compressor efficiency. Freecooling chillers that use inverter driven screw compressors enhance the energy efficiency of chilled water systems and consequently cut down electricity consumption.

![]()

Heat Recovery

Capturing and reusing the waste heat rejected by the IT equipment and cooling systems.

Heat recovery can increase the efficiency of the chilled water system by allowing heat captured from the data center to be reused for other purposes. Instead of cooling the heat load, heat is effectively captured by the system and can be used to meet heating demand in other parts of the building, neighboring buildings, or a district heating network.

![]()

Cooling Storage

Add cold water storage tanks.

Cold water storage tanks are an effective means for reducing energy consumption, as these tanks serve as thermal energy storage (TES) that help alleviate power plant loads during peak demand. Facilities ramp up their chiller systems at night to make cold water, taking advantage of lower night-time rates. These facilities then rely on this stored cooling capacity for day-time cooling.

Visit Vertiv’s Chilled Water Customer Experience Center in Piove di Sacco, Italy!

Visit our virtual Thermal Management Customer Experience Center which features a complete, customer-centric, advanced technology solutions testing area. Experience the capabilities of our Chilled Water data center innovations at peak conditions.

Choose your avatar and start your virtual journey in the Freecooling Chillers Innovation Lab or in the Large Indoor Innovations Lab and chose and simulate your Witness Test as if you were there inside!

![]()